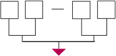

Every Mini-Mover conveyor, whether Lite Series and Low-Profile Series platform, is built to order. Each complete conveyor unit is comprised of three (3) hardware building blocks: conveyor module, belting and drive package. The Model Number system, illustrated below, assists both customer and factory to identify the exact hardware components and the application requirements to be met in the complete, assembled unit. Conveyor selection is a 1-2-3 configuration process in which the customer receives full sales engineering guidance every step of the way.

Conveyor Ordering Guide

Conveyor Module

The module is the units foundation, consisting of siderails, bedplate, pulley assemblies and drive shaft . Choose platform, dimensions and hardware preps that meet the intended drive package and application needs.

Model Number Key

Belting

Selection of the right belt material helps ensure the final conveyor unit will perform the needed functions. Flat belting is available in many types to suit varied situations. Once the fundamental flat belting is chosen, cleats may be selected in the style and configuration to best move product.

Model Number Key

Drive Package

Many factors influence drive package selection, such as electrical supply, space requirements, size of the product to be moved and safety needs for certain environments. We offer a wide variety of gearmotor combinations to meet almost any situation.

Model Number Key

Example of Model Numbers

| Lite | Module & Belt | 20-06036-R-N U1-H1/4 | Lite Series, 06″ wide by 36″ long, drive shaft on Right side; T-Slots not available on Lite. Belt is flat U1-style white urethane, with H1 style cleats (0.79″ high) spaced every 4″ |

| with Drive Package | RI-180A-20-10 | Right-side Integrated (direct mount) drive, 180:1 gear ratio (3 fpm), 25 Watt motor for 115/50-60/1 VAC input, and equipped with standard fixed-speed controls |

| LP | Module & Belt | 40-12144-L-D P1 | LP Series, 12″ wide by 144″ long, drive shaft on left side, Dual T-Slots. Belt is optional flat P1-style black PVC. |

| With Drive Package | LU-025B-20-11 | Left-side undermount drive, set at 45°, 25:1 gear ratio (7 to 22 fpm), 40 Watt motor for 115/50-60/1 VAC input, and equipped with optional variable-speed controls. |

Factory Use Codes: Customer Modifications and Production Code

Optionally, Lite and LP Series conveyor platforms can be modified for specific application requirements. The special 4-digit fields (shown in gray color above) will be absent in the Model Number of a standard conveyor.

However, when modifications are made to the Module hardware, a 4-digit Customer Modifications code is added to the Model Number to keep a factory record of the hardware changes made, for future customer service purposes. When modifications are made to the Drive Package, a 4-digit Production Code will be assigned to keep a factory record of the electrical and/or hardware changes made, for future customer service purposes.